|

|

|

|

|

|

|

|

|

PCT Expansion 2012-2015

All content from PCT website

Over the past few years, Canadian supplies of sulphur have been diminishing. To continue to support our business and in turn, the Port Moody community, PCT has been exploring a number of alternative commodities including potash and food-grade canola oil. Both commodities align with our current terminal operations and will not require a fundamental change to our operations. We will continue to use the same on-site technology that is currently being used to handle ethylene glycol and sulphur. In addition, PCT has a history with potash: we handled the commodity between 1965 and 1971. To handle these new products, our facility will require a few modifications, including the construction of a potash storage shed and additional liquid storage tanks. The facilities will be located beside our existing sulphur piles on the east side of our property. Modifications to existing terminal infrastructure will include upgrades to our water treatment facilities and shiploading equipment. When investigating alternative commodities, our primary goal was to find an option that would work within our existing systems and award-winning environmental and safety policies. Both potash and canola oil allow us to continue to use our state-of-the-art operational systems and processes that have drastically reduced air emissions and improved the marine ecosystems and habitat surrounding the terminal. PCT is committed to maintaining our relationship with the community – ensuring that our residents are kept informed of changes that are taking place at our facility is our top priority. Project Timeline:

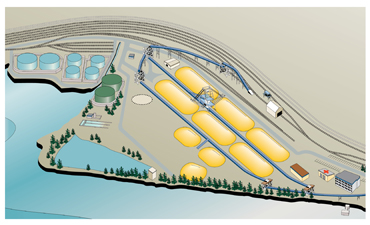

Before

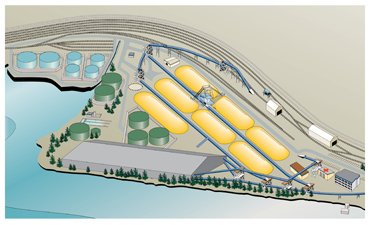

After Handling Food-Grade Canola OilThe canola oil that may be handled on the PCT site is a food-grade vegetable oil. Canola is a yellow flowering plant, which produces seed-filled pods that are rich in oil. These seeds are crushed and pressed yielding the high-value oil consumed worldwide.

The same on-site technology that is being used to handle liquid ethylene glycol will apply to canola oil. The reduction of ethylene glycol product on site has resulted in the availability of two storage tanks that can used to handle other liquid products. Canada is the largest canola producer in the world, producing up to 15 per cent of the world’s annual supply and contributing over $13 billion to the Canadian economy. It is anticipated that PCT will handle up to 750,000 tonnes of canola oil annually, on its way to markets primarily in Asia.

Handling PotashPotash is a non-toxic potassium salt, mostly used as a crop nutrient in agriculture worldwide. Potassium is the seventh most abundant element in the earth’s crust and is the primary source element in potash. Canada is the world’s largest producer of potash with Saskatchewan producing 90 per cent of the country’s totally output.

It is anticipated that PCT will handle up to 2,150,000 tonnes of potash annually, on its way to markets in Asia and other parts of the world. Project RenderingsTo handle these new products, our facility will require a few modifications, including the construction of a potash storage warehouse. The renderings below reflect the proposed size, shape and colour of the warehouse:  Permitting ProcessPCT will prepare a Project Permit Application to Port Metro Vancouver (PMV) that will outline the modifications to our existing site and will include an Environmental Assessment Document (EA) that will examine impacts and evaluate environmental mitigation strategies. PMV will review the application and consult First Nations, the City of Port Moody, Metro Vancouver, Province of BC, and Federal Regulators obtaining input before approving or denying PCT’s permit application. PCT will also apply to Metro Vancouver (GVRD) to amend our water discharge and air emissions permits

Terminal Improvements and ModificationsTerminal modifications and upgrades will include: o A new railcar unloading station including specialty equipment to unload potash railcars. o New conveyor systems to transport potash from the railcar unloading station to the new storage warehouse and from the warehouse to our existing shiploading system. o New storage warehouse is proposed to be approximately 85 metres wide, 265 metres long and nearly 33 metres tall. The building will to store up to 160,000 metric tonnes of potash fertilizer sorted into three separate grades. o Modifications to the shiploader and conveyors to add environmental covers and provide dust-free loading. o Extension of rail track west of the terminal to accommodate trains up to 2600 metres in length. o Upgrades to our water treatment system to increase water storage capacity and efficiency with a new storage tank. o Deepening of the Port Moody Arm shipping channel to 13.5 metres to improve vessel safety. o New tank car unloading equipment to allow top unloading of liquid railcars. o Construction of three additional tanks (38 metres in diameter and 15 metres tall) to provide storage for up to 50,000 metric tonnes of food-grade canola oil. o New liquid shipping lines from storage tanks to the vessel-loading facility at Berth #1. o New articulated marine-loading arm for shiploading of food-grade canola oil. o Installation of over 325 metres of floating containment boom to provide vessel containment during loading, as required in our handling procedures

FAQsWhy is PCT expanding the products it handles? Although global demand for sulphur remains very strong, western Canadian supplies of sulphur from gas processing are decreasing and are forecasted to continue to do so for the near future. PCT has handled more than 1,000,000 metric tonnes per year of ethylene glycol, however volume in the past two years has reduced significantly due to a handling contract which expired in 2010 and was not renewed. PCT has been exploring alternative commodities to grow our business that align with current operations and can also support local operations until sulphur and ethylene glycol volumes return. While contract negotiations are still underway with potential clients, PCT wants to be proactive in keeping residents informed as to potential changes on our site and to seek feedback on our plans. Why potash? PCT has a history of handling potash and is familiar with the commodity and its handling procedures. The technology currently used to handle sulphur applies to potash. As the handling process is the same, we will be able to ensure our award-winning commitment to safety and our exceptional environmental record is maintained. How will potash be handled? Potash will be transported to our Port Moody facility by train from Saskatchewan. Incoming trains will be unloaded via a new unloading system and transported by conveyors to a storage warehouse that will be constructed that will be required as potash is water-soluble. From the storage warehouse, potash can be transported to vessels via a covered conveyor system. Why food-grade canola oil? The reduction of ethylene glycol shipments has resulted in capacity on site that can be used for handling other liquid products. All technology used to handle ethylene glycol applies to food-grade canola oil. As the handling process is the same, we will be able to ensure our award-winning commitment to safety and our exceptional environmental record is maintained It is anticipated that PCT may handle up to 750,000 metric tonnes of food-grade canola oil, on an annual basis, that will be shipped to markets primarily in Asia. How will the food-grade canola oil be handled? Handling of food-grade canola oil will be done through a closed loop system, the same handling procedure for ethylene glycol. Incoming trains will be unloaded and food-grade canola oil pumped to storage tanks. PCT will be constructing up to three new additional tanks, which are proposed to be slightly larger than the existing tanks. From the storage tanks, food-grade canola oil will be transported to vessels via a pipeline system. What construction will be done on site? o A new railcar unloading station will be built with specialty equipment to unload potash railcars. o New conveyor systems to transport potash from the railcar unloading station to the new storage warehouse and from the warehouse to our existing shiploading system. o New storage warehouse is proposed to be approximately 85 metres wide, 265 metres long and nearly 33 metres tall. The building will to store up to 160,000 metric tonnes of potash fertilizer sorted into three separate grades. o Modifications to the shiploader and conveyors to add environmental covers and provide dust-free loading. o Extension of rail track west of the terminal to accommodate trains up to 2600 metres in length. o Upgrades to our water treatment system to increase water storage capacity and efficiency with a new storage tank. o Deepening of the Port Moody Arm shipping channel to 13.5 metres to improve vessel safety. o New tank car unloading equipment to allow top unloading of liquid railcars. o Construction of three additional tanks (38 metres in diameter and 15 metres tall) to provide storage for food-grade canola oil. o New liquid shipping lines from storage tanks to the loading facility o New articulated marine-loading arm for shiploading of food-grade canola oil. o Installation of over 325 metres of floating containment boom to provide vessel containment during loading, as required in our handling procedures What type of vessels will be used to transport potash and food-grade canola oil? Potash will be loaded into bulk carriers of the same size and configuration as the existing sulphur vessels. Vessels capable of carrying up to 70,000 metric tonnes of potash can be loaded at PCT. Food-grade canola oil will be loaded into liquid parcel tanker vessels of the same size and configuration as the existing glycol vessels. Vessels capable of carrying up to 45,000 metric tonnes of bulk liquid can be loaded at PCT. What type of trains will be used to transport potash and food-grade canola oil? Potash will be transported via specialty built railcars similar to those carrying grain and other dry bulk commodities. Food-grade canola oil will be transported via closed rail cars – similar to the cars that are currently used to transport ethylene glycol. Will there be additional train and vessel traffic as a result of handling potash and food-grade canola oil? There will an increase of both train and vessel traffic for potash and food-grade canola oil, but activity will remain below peak traffic levels seen between 2003-2008. Will PCT continue to ship sulphur and ethylene glycol? Yes, handling sulphur and ethylene glycol will remain our core business. Does PCT require environmental permits to do this? An amendment to PCT’s current Air Emissions and Water Discharge Permits, issued by Metro Vancouver, is required. Both Metro Vancouver permits will contain the same restrictions on water and air quality but not the addition of new products being handled on site and control equipment used. A Project Permit Application will be submitted to Port Metro Vancouver that will contain details on what the project will mean for their property. An Environmental Assessment (EA) Document will accompany the permit application and will report on social and environmental impacts the project will have. Port Metro Vancouver will consult First Nations, the City of Port Moody, Metro Vancouver, Province of BC and the Federal Regulatory Bodies for input prior to making their decision on the permit application. What is PCT doing to mitigate environmental concerns? As the handling process for potash and food-grade canola oil is very similar to the current products we handle, we will be able to ensure our award-winning commitment to safety and our exceptional environmental record is maintained. PCT will be using best practices in the facility design and utilizing the best available control technology to mitigate environmental concerns. How will this impact the surrounding community? Our relationship with the community, safety and the environment remain our top priorities. As you have come to expect from us, we will provide transparent and regular communications to our stakeholders via our website and newsletter on the handling of potash and food-grade canola oil. Residents will in all likelihood not notice any impact or change at PCT other than the presence of new equipment and buildings. When complete, operationally this new business will integrate into our terminal seamlessly. What is the impact on the local economy? Currently PCT contributes approximately $1 million in taxes on an annual basis to the City of Port Moody. New business at our facility may result in future contributions of up to $2 million per year. It is anticipated that the new business will result in up to 90 new full-time equivalent jobs in Port Moody. Does the community have the opportunity to provide feedback? PCT is committed to sharing information about our new business development and listening to Port Moody’s residents through both face-to-face and online feedback opportunities: - The company’s website will continue to have regular updates on changes that are being proposed for the site with comments being requested. - Special “Community Updates” will be mailed to all Port Moody residents and businesses outlining proposed changes with comments being requested. - PCT will remain active on their Facebook Page and Twitter Feed with timely and relevant information. It is anticipated that negotiations with potential project partners will be finalized in the fall and a public Open House will then be held with detailed designs and plans available for viewing and comment. Where can I get further information and ask additional questions? Diana Dilworth Community Relations Coordinator 604-931-9253 We Want to Hear From You:

More information will be shared at a public open house planned for the fall. In the meantime, community feedback is welcome – please contact us! Diana Dilworth Phone: 604-931-9253 |